Overview:The hot a ir enters into the bottom of the dryer in tangent direction.Under the driving of the stirrer,a powerful rotating wind area is formed.The paste s tate materials enter into the dryer through the s crew charger…

Consulting

DESCRIPTION

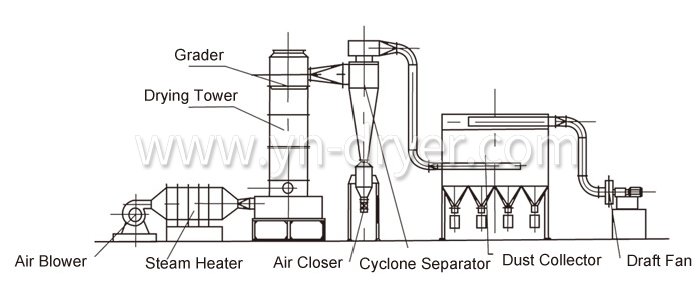

XZG Series Spin Flash Dryer is continuous drying equipment specially designed for shaped cake, cream paste, and paste slurry materials. The clean heat medium goes into the drying room from the tangent direction and creates a strong rotary vortex air current when it’s in motion with the stirrer. The wet material is added to the drying room in a fixed quantity, and it will be crushed and dry under high speed stirring action. The top of the drying room has particle size classification, the big particles will be stopped by the classifier and the fine powder will be discharged from the center of the ring and collected by the cyclone separator. The big particles will return to the drying room and continue to be crushed and dry.

FEATURES

(1) The raw material is processed by cutting, shearing, blowing, floating, and rotating, then become granulated shape and separated greatly; the relative velocity between solid phase and gas phase is great, this strengthens the process of heating exchange.

(2) Design with compact structure and required small occupied area, and the machine is easy to control and maintain.

(3) The hot air enters into the bottom of machine and creates strong rotating airflow; it can wash out material that sticking on the inside surface.

(4) The high temperature area is at the bottom of the machine, the heat sensitive raw material will not directly contact with heating surface. As a result, carbonization and color change problems can be solved.

(5) The dryer is running under negative or micro negative pressure, there is no need other crushing machine to crush raw material, and the circumstance pollution will not occur.

(6) A segmenting ring and a rotational flow piece are equipped in the upper drying room in order to control granulated size and final moisture to satisfy required moisture containing rate and granulation.

WORKING PRINCIPLE

The hot air enters into the bottom of the drier in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. The paste state materials enter into the drier through the screw feeder. Under the powerful function of the stirring vanes at high-speed rotation, the materials are distributed under the function of strike, friction and shearing force. The cake state materials will be smashed and contact the hot air fully and the materials are heated and dried. The dehydrated materials will go up with the hot-air flow. The step rings will stop and keep the big particles. Small particles will be discharged out of the drier from the center of the machine and the material will be collected by cyclone separator of dust collector. The wet or big particles will be swing towards to the wall by the centrifugal force function and the materials will be crushed again after fall down to the bottom.

APPLICABLE MATERIALS

Organics: Atrazine (Pesticides), Cadmium Laurate, Benzoic Acid, Germicide, Sodium Oxalate, Cellulose Acetate, Organic Pigments, and etc. Dyes: Anthraquinone, Black Iiron Oxide, Indigo Pigments, Butyric Acid, Titanium Hydroxide, Zinc Sulfide, Azo Dye Intermediates, and etc. Inorganic: Borax, Calcium Carbonate, Hydroxide, Copper Sulfate, Iron Oxide, Barium Carbonate, Antimony Trioxide, Metal Hydroxides, Heavy Metal Salts, Synthetic Cryolite, and etc. Food: Soy Protein, Gelatinized Starch, Lees, Wheat Sugar, Wheat Starch, and etc.

TECHNICAL PARAMETERS

| Item \ Model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Tower Diameter (mm) | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air amount (M3/h) | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Water Evaporation (kg/h) | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

| Total Power (kW) | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Max. Equipment Height (m) | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Occupied Area (m2) | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note:

1. The evaporated amount of moistureis calculated when the temperature of inlet is l80oC and Ihe temperature of outlet is180oC and the temperature of outlet is 180oC;

2. Besides the models above mentioned, special specification can also be made as request;

3. The equipped capacity above mentioned is standard. The power can also be decreased in accordance with pracitcal condition.

Raw Material Example & Characteristics (based on Model XZG-6)

| Item \ Raw Material | Stearate Acid | Aluminum hydroxide | Zinc Carbonate | Monosultap | TMTD |

DSD Acid |

Red Iron Oxide |

Antimony Dioxide |

Cuprous Chloride |

White carbon black |

| Inlet Air Temperature (oC) | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Primary Moisture (%) | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final Moisture (%) | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Practical Drying Capacity (kg/h) | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Item \ Raw Material |

ZDC accelerant ZDC |

Oil soluble ink |

Substitute Zinc Manganate |

Phthaloc- yanin dye |

Calcium citrate |

Superfine calcium carbonate |

Slurry treatment agent |

Sodium isocyanurate dioxide |

Sodium isocyanurate trioxide |

| Inlet Air Temperature (oC) | 150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

| Primary Moisture (%) | 60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

| Final Moisture (%) | 0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

| Practical Drying Capacity (kg/h) | 80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

SelectionThe belt dryer has a wide range of applications. At present, it has its place in the fields of pharmaceuticals, food, biology, chemi…

Drying equipment is widely used in industry. In many fields, the use of drying equipment is required. Similarly, drying equipment also plays …

As the worlds energy consumption increases year by year, the combustion of coal as a primary energy source releases a large amount of sulfur …

ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device of Chinese medicine ex…

Although the belt dryer is currently a more efficient and energy-saving dryer, there will be failures in actual operation. What we do is to f…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…